What is date code label?

1.🤔What is the LOT CODE?

LOT CODE is also called LOT No., LOT No. is the abbreviation of lot number, which means "lot number". In order to trace and review the production history of the batch of components, so each batch of products have the corresponding production number.

The production lot number is the number of components in the same batch. It is a set of numbers or letters plus numbers used to identify the "batch". In general, according to the batch number can track the production of the product (production date, quality level, factory time, origin, etc.).

Now most companies are gradually unifying the production date and production lot number of components. The lot number and D/C form given by different original manufacturers are different.

2.🚩Device package marking

Figure 6-1 shows the Xilinx Logo; Family Brand Logo; the first line is the product model silkscreen; the second line includes the package,bare chip version, fab code, D/C, etc.; the third line uses a 10-character LOT CODE to indicate the package location and batch information

Figure 2

Figure 2 shows the CYPRESS chip silkscreen information; lines 1 and 2 are the model number, line 3 is the D/C and lot number, and line 4 is the origin.

Figure 3

Figure 3 shows the TI chip screen printing example, Lot trace code where YM is the assembly time D / C, LLLL is the assembly factory

Figure4

Figure 4 shows that the LOT NUMBER is printed on the outer package, and the LOT CODE contains the batch and origin information

Figure5

Figure 5 illustrates the Altera LOT number, which contains the package test plant code, bare version information, D/C information, etc

Figure6

Figure 6 shows the Atmel screen printing information. The top screen printing is D/C, product information, and the bottom screen printing is LOT NUMBER including origin

Figure7

Figure 7 shows the LOT number of SPANSION including D/C, assembly place and other information.

Figure8

Figure 8 shows the Micron silkscreen style, including D/C, origin, bare version and other information LOT NUMBER

Figure9

Figure 9 shows that the Label Content of Micron LRDIMM series products includes lot numbers such as D/C and assembly place

Figure10

Figure 10 shows Lattice Datecode (LotID) Format

Figure11

Figure 11 shows the LT D/C LOT number format

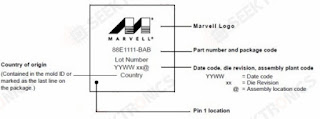

Figure12

Figure 12 shows the Marvell LOTnumber D/C silkscreen format

Figure13

Figure 13 illustrates Pericom lot number, including factory code, bare-piece, D/C, fab code, etc.

Figure14

Figure 14 shows the ST D/C origin and other information.

3.📦Batch information representation

Batch is a batch of the same variety and the same specification of products produced on the same shift and the same production line with the same batch number of raw materials.Relative to the components in a narrow sense is the date of production screen printed on the surface of the chip or the date on the outer packaging label by the packaging and testing factory. We believe that the batch is DTAE CODE for short D/C, generally speaking, the batch information of the component is expressed as follows:

① Use a alphabet to indicate the year Y

Figure15

Figure 15, the D/C silkscreen on the EPSON crystal indicates the last digit of the natural year with the corresponding letter, for example, with F for 2006 or 2016.

② One character is used to indicate the year/week (Y/W).

Figure 16

Figure 16 shows the HP RF transistor D / C screen printing method. Which uses 5 years as the cycle, D on behalf of January 1999, January 2004, January 2009, etc..

③ with two characters to indicate the year/week (Y / W).

Figure17

Figure 17 in the ON chip silkscreen information, Y: Year Date Code, W: WorkWeek Date Code.

Figure 18 shows: ON for the silkscreen characters to determine the year and week code, the left part of the figure is the year, the right part is the week. For example: KD will indicate the 4th week of 2007.

④ with two characters to indicate the year/month (Y / M).

Figure19

Figure 19 shows the TI chip silkscreen information, Lot trace code where "97" indicates D / C information, 9 for the year code, 7 for the month code

⑤ with three characters to indicate the year week (Y / WW).

Figure20

Figure 20 shows the Maxim chip screen printing legend, YWW indicates D / C, year week week form, such as 927 indicates 27 weeks in 2009.

⑥ 4 characters are used to indicate the year/week (YY/WW).

Figure21

Figure 21 shows an example of Infineon chip screen printing, the last 4 characters in the second line that D / C, such as 0525 for week 25, 2005.

4.🤨Common problems about batches in work

Often encountered in the work of common customer batch requirements are: the same batch, batch requirements within a few years, you may ask, why the same thing customers have such requirements?

① Same batch.

In the component production process, due to the existence of different wafer fabrication plants, different wafer foundries, different packaging and testing plants, although the design drawings, software, raw materials and processes are the same, but each batch of feeding production out of the product, there are still differences in quality and performance. The same batch determines the same parameters, the same production process, the same assembly plant, the same MSL, the same soldering process, which can ensure a high degree of consistency in the performance of the chip.

Customers who generally require the same batch are mainly involved in military enterprise customers, especially in the aerospace field, which have high quality products, harsh use environment, very high requirements for stability, and correspondingly high requirements for components. Aerospace products, product value is huge, dangerous, can not bear the impact of device failure. Domestic aerospace products, key devices into the warehouse before the DPA destructive experiments, must be the same batch, identical products inside, a certain percentage of randomly selected products to do testing to be representative, in order to ensure that the subsequent production of materials to fully meet the parameters of demand.

②Batch requirements for several years.

Generally speaking, any product has a warranty period. The warranty period is the period during which the components are able to work properly under the given storage and transportation conditions after being packaged and shipped from the packaging plant. The lot of the component determines whether the lot of material is under warranty. Poor storage and transportation conditions and random unpacking can cause moisture and oxidation of the tube pins in the warranty period. Moisture, pin oxidation of the components in the welding, affected, resulting in false welding, or even chip damage phenomenon.

More domestic production-oriented enterprises on the material batch requirements within two years, these customers are mainly involved in the industrial and civilian sectors, their product stability requirements are not as high as the military industry, but also a certain fault tolerance rate, but in order to make their own product quality better and better to win market share and reputation, many companies have made the component batch requirements within two years, so as to reduce because the chip production out, in the sales and Preservation process, due to a variety of external factors caused by the chip performance damage, reduce the quality of the product caused by material problems hidden. And older batches of materials, if the use of problems, because of the long factory time, in the market may be after many transactions, can not effectively contact the original factory through the transaction chain, if there are various problems, the need for the original factory to provide technical support, it is also difficult to get the original factory cooperation.

5. ✍The role of Lot number in the work

Lot number is a very important record information in the process of chip circulation, and is one of the most important certificates for after-sale service after the chip is used.

For distributors, it is also necessary to record the batch information of purchased and sold products from the perspective of protecting their own interests. For distributors, the purchase of models, especially in the case of spot purchase, the procurement channel often buy the same model from different channels for various reasons such as price, batch, packaging and out of stock, and customers often have a similar situation. When customers use the product, the quality or channels have questions, we can confirm whether the product is our company sold to customers through the batch information on, can not customers from our bought models, said there are problems must be we supply the past. If it is confirmed that Seektronics supply, we can also check the batch information to find out from which channel our company purchased the goods at that time, and the supplier to make timely feedback

For custmers, recording the incoming batch of suppliers can facilitate production pickup by prioritizing the use of older batches of chips to ensure that the chips in stock are the latest batch numbers. It is also convenient to find out the source of supply in time if there is any problem in the subsequent use, to confirm the whole transaction chain from the original factory to the customer, and to provide early feedback to the original factory through the transaction chain to solve the problem in use.

Comments

Post a Comment