1.What is an integrated circuit?

An integrated circuit (IC) is a miniature electronic device or component. Using a semiconductor process, the transistors, resistors, capacitors, inductors, and other components and wiring required in a circuit are fabricated on one or more semiconductor wafers and then packaged in a housing to form a miniature structure with the desired circuit function. Integrated circuits are usually denoted by the letters "IC" and their function is to process the input information.

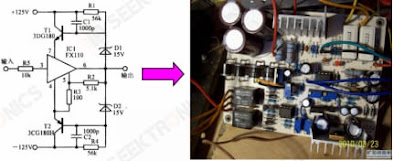

Let's take a look at the circuit diagram and circuit board of a discrete device.

Imagine if you could miniaturize the circuits composed of these discrete semiconductor devices and then make them together? As early as 1952, British scientist G. W. A. Dummer proposed the idea of integrated circuits, and in 1958 TI's Clair Kilby's research group invented the first integrated circuit, containing 12 components, using germanium semiconductors. The next few decades saw rapid development of integrated circuits and now integrated chips containing billions of transistors are commonplace, with chips like the Huawei Kirin 1020 and the Apple A14, which use a 5nm advanced process, reaching more than 10 billion transistors.

MCU (Microcontroller Unit) as an example to further understand the structure of the chip, micro control unit, also known as a single chip microcomputer (Single Chip Microcomputer ) or a single chip, the chip contains a microprocessor (CPU), and the memory (memory), counter (Timer), PLL, A/D conversion, UART, DMA and other peripheral interfaces Integrated on a single chip to form a chip-level computer for different applications to do different combinations of control.

The diagram below shows the structure of the MCU chip.

Through the chip layout and microscope magnification picture to understand the chip inside what kind of length, the following figure is a variety of different process chip layouts. A number of different process chip layouts. Then look at the microscopic photos of the IC chip.

Chip microscope photos

2. Integrated Circuit Industry Chain

The IC industry consists of three major industries: design, manufacturing, and packaging, in addition to additional industries such as semiconductor materials, devices, equipment, and design software tools.

In the early days, most of the semiconductor companies were Integrated Device Manufacturers (IDM), which were responsible for IC design, manufacturing, packaging, testing and sales. Typical IDM factories include Intel, TI, Motorola, Samsung and other companies.Due to Moore's Law, the design and production of semiconductor chips became increasingly complex and costly, and a single semiconductor company often could not afford the high R&D and production costs from upstream to downstream. IC design) and DESIGN SERVICE model (chip design service provider). Well-known foundries (Foundry, generally responsible for only one part of manufacturing, packaging or testing) are TSMC, UMC, Charter, SMIC, Sunrise, SPIL, Changdian Technology, Huatian Technology, etc. Well-known FABLESS are Qualcomm, MediaTek, Broadcom, Huawei, AMD, etc. Well-known DESIGN SERVICE are ARM, Imagination, Synopsys, Cadence, Mentor Graphics, etc. The following figure shows the division of labor of the three major industries.

3. IC general classification

ICs can be divided into analog ICs and digital ICs in terms of circuit characteristics, such as operational amplifiers are analog ICs and encoder chips are digital ICs, but of course, many chips are designed with a mixture of both. The degree of customization can be divided into semi-custom ICs and fully customized ICs, FPGA / CPLD belongs to semi-custom chips, typically characterized by user-programmable change of internal logic, ASIC (special-purpose integrated circuit) belongs to fully customized chips, general-purpose CPU, GPU is also generally fully customized chips, they are characterized by once the design and manufacture of the circuit is fixed, can no longer be changed. In fact, regardless of whether it is analog, digital, or a mix of both, any custom chip is an ASIC. soc (system-on-chip or system-on-chip) can be implemented in FPGAs or designed as an ASIC, which generally includes digital logic design and analog circuit design.

4. Digital IC development process

The general flow of digital IC R&D is as follows: firstly, the specification is customized (set the target), then the functions in the specification are described in a hardware description language, whether the functions realized by the code meet the expectation needs to be simulated and verified, and if the functions of the code are found to be inconsistent with the specification, the design needs to be modified until the functions are correct after the verification is passed, the RTL code is integrated into the process-related gate-level circuit, and the gate-level netlist needs to do After verification, the RTL code will be synthesized into process-related gate-level courses, and the gate-level netlist will be verified by functional verification and formal comparison, and the layout and wiring of the back-end can be carried out only after the verification is passed.

5. Integrated IC design-related knowledge

Integrated IC involves a wide range of knowledge, human energy is limited, a person is unlikely to master all the knowledge, so we need to be selective in learning, the work needs to use those points of knowledge to learn those points of knowledge first, learn while using, grow in practice. Chip design-related knowledge points are rough as follows. System knowledge Computers, communication, information, control, and other disciplines.Programming knowledge Verilog/VHDL Scripting language (TCL, Perl, Python, etc.)Circuit knowledge analog, digital, analog-digital hybrid, RFIC, MMIC.Tool knowledge cadence, Synopsys and other software tools.Process knowledge Component characteristics and models, process principles and procedures.Linux knowledge of Linux basic operation.

Comments

Post a Comment